Welding is a necessary skill in many industries, including construction, manufacturing, and repair work. However, it’s important to remember that it can be a hazardous job if proper safety precautions aren’t taken.

Don’t worry though; read on for our top tips on the best practices for welders to operate safely:

Wear Protective Gear

The first and most important step in joinery safety is to wear the correct personal protective equipment (PPE). This includes flame-resistant clothing, such as heat-resistant gloves and boots to protect you from flying sparks and hot metal. Additionally, you will need a welding helmet with a filter lens that protects your eyes.

Ensure Proper Ventilation While Welding

The process usually produces fumes and gases that can be harmful if inhaled. Ensure you’re working in a well-ventilated area or use a welding fume extractor to remove the fumes and gases from your workspace.

Keep Your Work Area Clean And Organised

A cluttered workspace can cause accidents and injuries. Keep your work area clean and organised to minimise the risk of tripping over objects or accidentally knocking something over.

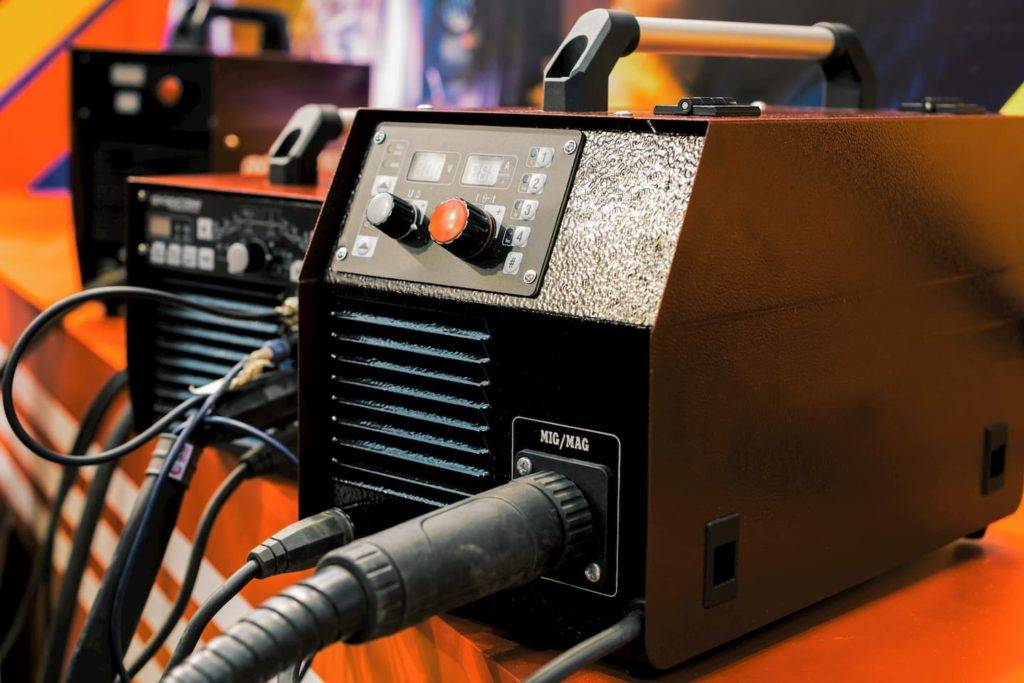

Inspect Your Welding Equipment Before Use

Always inspect your equipment before use. Check that your machinery, wires, and connectors are in good working condition, and replace any damaged parts immediately.

Fire Safety

Welding produces heat and sparks, which can ignite nearby flammable materials. Know your fire safety procedures. Make sure to keep a fire extinguisher nearby and know how to use it in case of an emergency.

Keep a Safe Distance from Others While Welding

Much of the process involves hot metal and sparks that can cause burns and injuries to others. Always keep a safe distance from others while joining metals.

Do Not Operate In Wet Or Damp Conditions

Welding in wet or damp conditions can lead to electrical shock and other hazards. Always ensure your workspace is dry before starting any joining work.

Take Breaks When Welding

Industrial joining is a physically demanding job that requires focus and concentration. Take frequent breaks to rest and rehydrate, especially in hot and humid conditions.

Get Proper Training And Certification

Welding requires skill and knowledge. Get proper training and certification to ensure you’re working safely and efficiently. Proper training will also teach you how to identify hazards and how to prevent accidents.

Contact Us For High-Quality Welding Safety Equipment

Safety is crucial for welders. At Proweld UK, we’re committed to providing high-quality welding, engineering, and safety products. Contact us today to learn more about our products and services.